PRODUCTS

GVP is bringing to market the world’s largest composite high-pressure cylinders, enabling sizeable and efficient long-distance CNG, H2 and CO2 deliveries.

GVP’s cylinders vs state-of-the-art:

⦁ Transport more hydrogen (lower tare weight with bigger inner volume)

⦁ Has significantly longer service life because big cylinder can be repaired from inside (unique design enables entry through a manhole)

⦁ Provides lower levelized cost of ownership

GVP’s innovative technology allows:

⦁ Fast loading / unloading time (high temperature delta resistance)

⦁ Better efficiency (more delivered mass of H2 and minimized residual H2 pressure)

⦁ Durability (welded metal-to-metal neck connection)

⦁ Production of all types of cylinders dimensions (from very small to ultra-large cylinders)

⦁ Possibility for transportation of various industrial gases (H2 / CO2 / CNG, etc.)

Revolutionizing CO2 Transport: GVP’s High-Pressure Tank Solution

The energy transition isn’t just about switching to renewables - it's about building the infrastructure to decarbonize industries.

One of the biggest challenges?

Moving captured CO2 from distributed sources to centralized storage or utilization sites, without costly and energy demanding infrastructure and processes.

GVP has the answer.

Our containerized high-pressure tanks offer a modular, scalable solution for transporting CO2 without the need for liquefaction and purification. This approach drastically reduces both CAPEX and OPEX, enabling early deployment of CCS (Carbon Capture & Storage) projects - even before pipeline networks are built.

Key Benefits:

-

No liquefaction, no purification – CO2 is compressed and transported in dense phase at ambient temperature.

-

No cryogenic storage required - Avoiding complex refrigeration systems saves energy and cost.

-

Compatible with road, rail, barge, and ship - Seamlessly integrates into existing intermodal logistics networks.

-

Pipeline-ready — Delivers to entry points of high-volume CO2 pipeline systems or directly to offshore injection points.

-

Corrosion-resistant liner - Our AISI 304L stainless steel liner minimizes purification needs at capture sites.

Whether you're working on bioenergy with CCS (BECCS), industrial CO2 capture, or direct air capture (DAC), GVP’s solution enables faster deployment and better economics.

The result?

A flexible, scalable way to get CO2 moving - today. Interested? Let's connect.

Scalable Hydrogen Storage for Industrial Applications

As hydrogen gains momentum across energy, mobility, and industrial sectors, the need for cost-effective, high-volume storage is growing rapidly. But traditional storage solutions can’t keep up with the scale and costs efficiency demands of today’s energy transition.

GVP delivers the next generation of hydrogen storage.

Our world’s largest high-pressure composite tanks are designed to meet the needs of industrial hydrogen hubs, production sites, and buffer storage systems. Whether you’re producing green hydrogen or using it in refining, ammonia, or mobility applications - GVP’s storage solution scales with you.

Why it matters:

-

Higher Storage Volume - Our tanks hold significantly more hydrogen per footprint than conventional systems - improving land use and operational efficiency.

-

Cost Efficiency - Engineered to reduce storage cost per kg of hydrogen - both in CAPEX and OPEX.

-

Modular & Scalable - Easy to deploy in phased projects or expand as hydrogen production scales up.

-

Flexible Orientation - Can be mounted horizontally or vertically to fit your facility layout.

-

Robust & Low-Maintenance - Manhole openings for easy inspection, corrosion-resistant liner, and minimal maintenance downtime.

Built for industrial hydrogen ecosystems.

From electrolyzer output storage to refueling stations, production buffering, or integration with green ammonia or methanol production, GVP tanks provide reliable and efficient storage that supports your operations and accelerates hydrogen adoption.

👉 Ready to scale hydrogen storage at your site? Let’s talk.

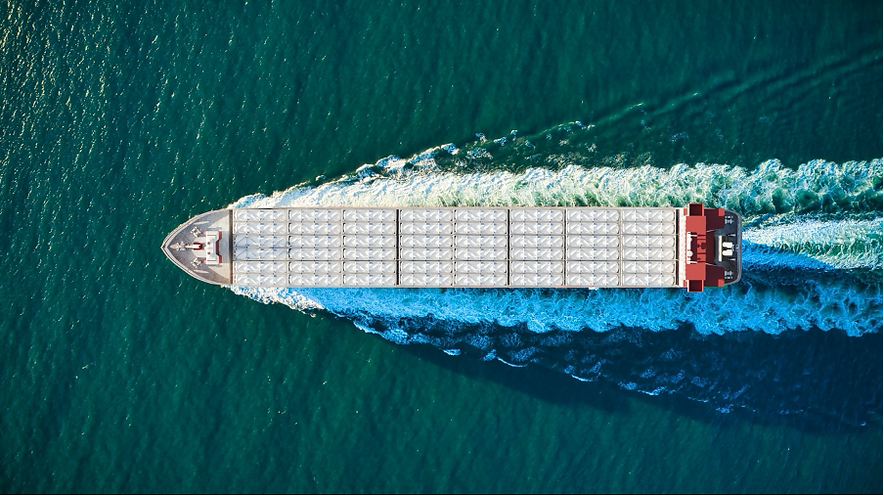

Unlocking Clean Gas Transport by Sea — Without Liquefaction

Long-distance marine transport is a critical piece of the clean energy puzzle.

As regions like Europe look to import low-cost hydrogen and other clean gases from global production hubs, the challenge remains:

How do we ship these gases efficiently - without relying on expensive, energy-intensive infrastructure?

GVP makes it possible.

Our containerized high-pressure composite tanks enable large-scale, efficient marine shipment of compressed gases like hydrogen, CO2, biomethane, and e-NG—without the need for liquefaction or chemical conversion.

What makes our solution unique?

-

No liquefaction or chemical conversion

No need to turn hydrogen into ammonia or methanol just to ship it. GVP enables direct transport in compressed form, reducing energy use and cost. -

Higher payload in each container

Our tanks offer the best-in-class volume-to-weight ratio, maximizing the amount of gas delivered per voyage. -

Certified for intermodal transport

Compliant with IMDG, CSC, and ADR/RID codes - safe and ready for ship, rail, and road handling worldwide. -

Modular and scalable

Ship a few thousand tonnes annually - or scale up to million ton. Our technology works flexibly across project sizes and stages. -

Avoid delays tied to permanent infrastructure. Deploy now, scale as needed.

Why this matters:

For H2, CO2, and e-NG markets to scale globally, we need agile, low-CAPEX transport solutions that work today.

GVP’s technology opens up marine corridors for clean gas trade - connecting producers to markets faster and more affordably.

👉 Interested in building a clean gas shipping route? Let’s connect.